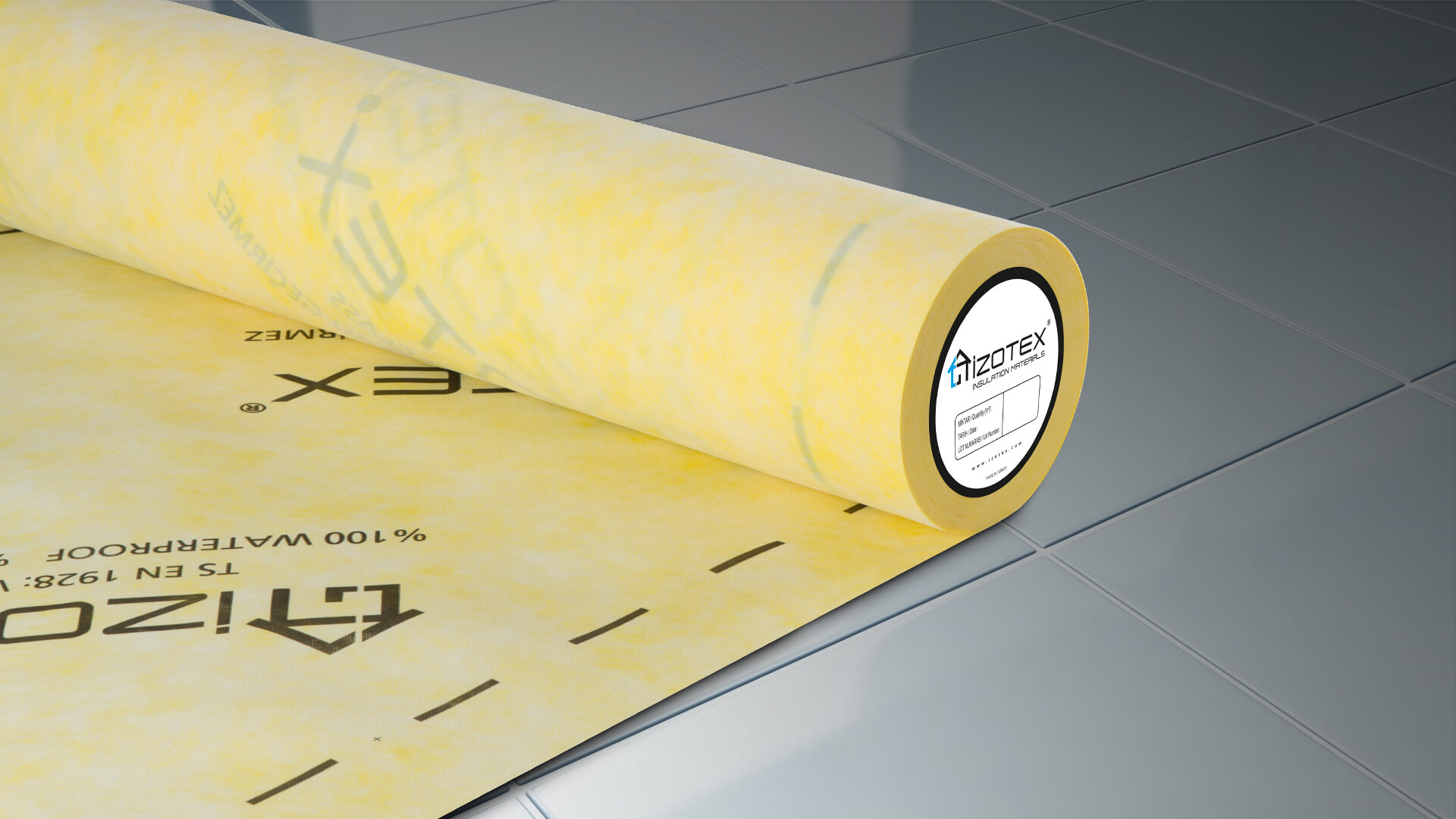

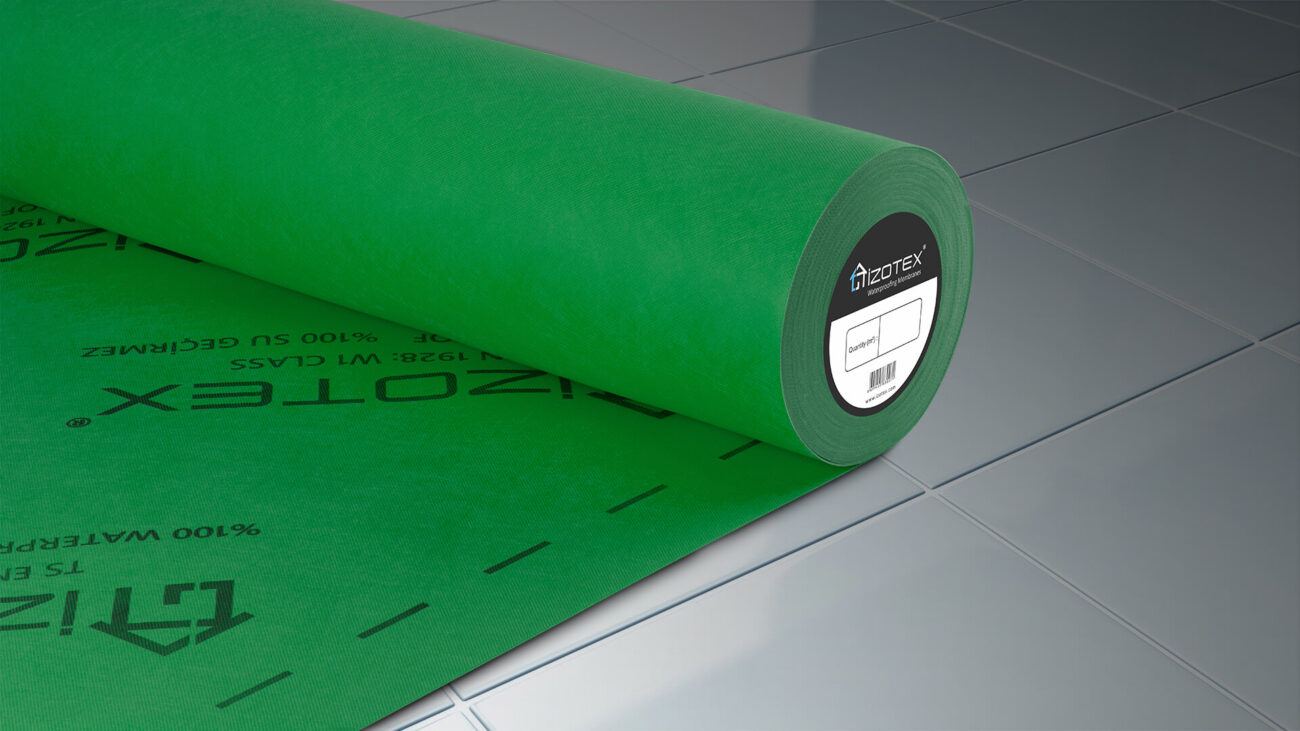

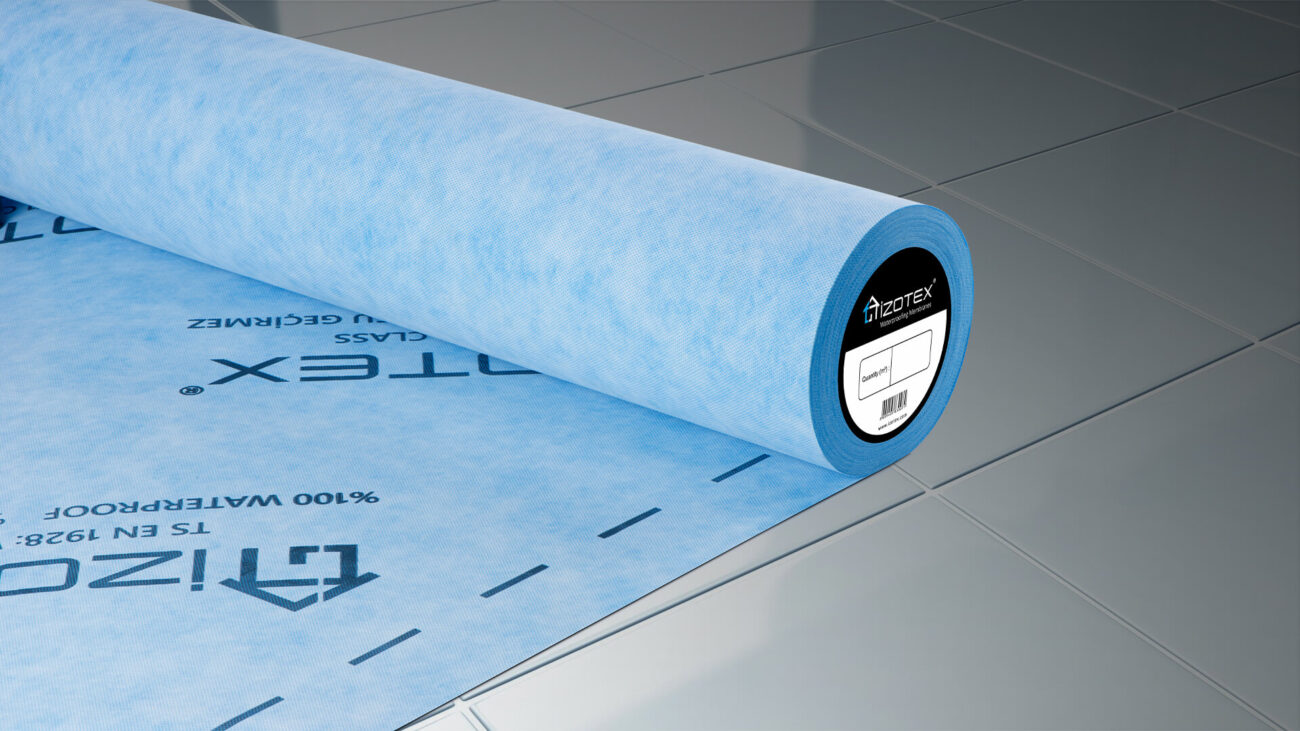

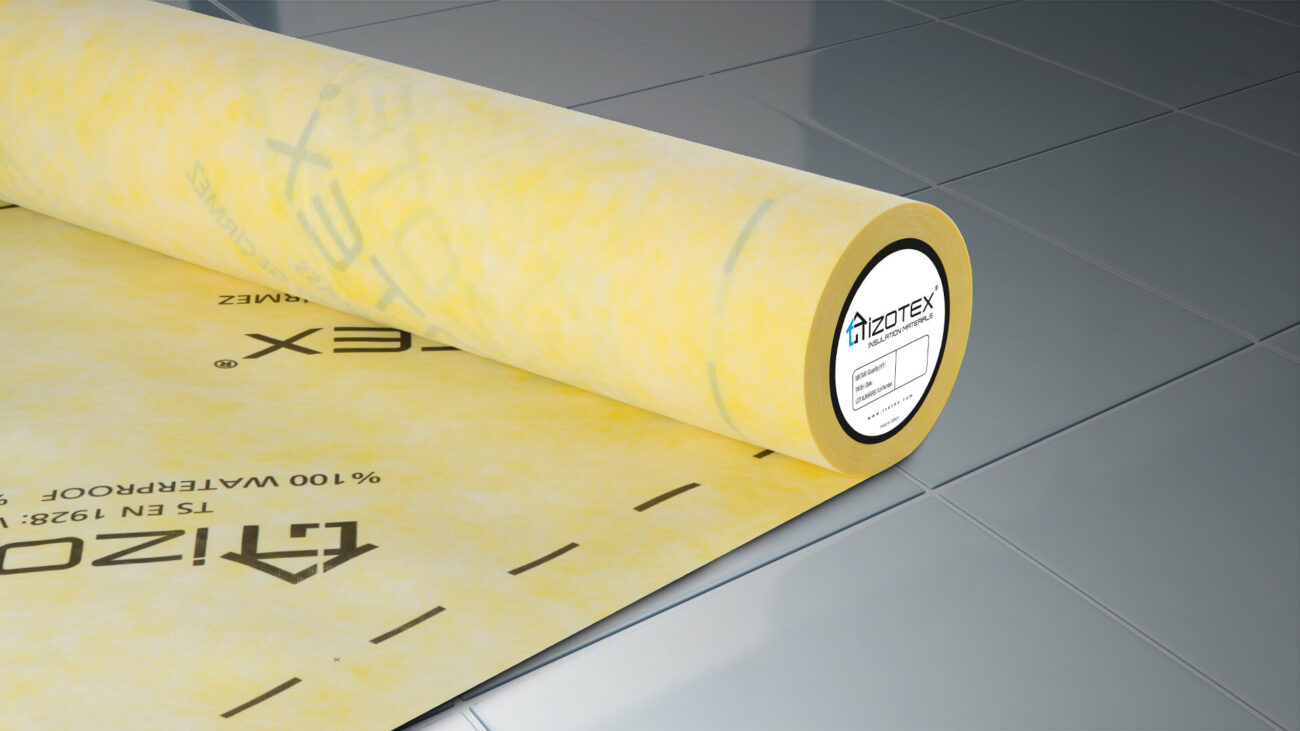

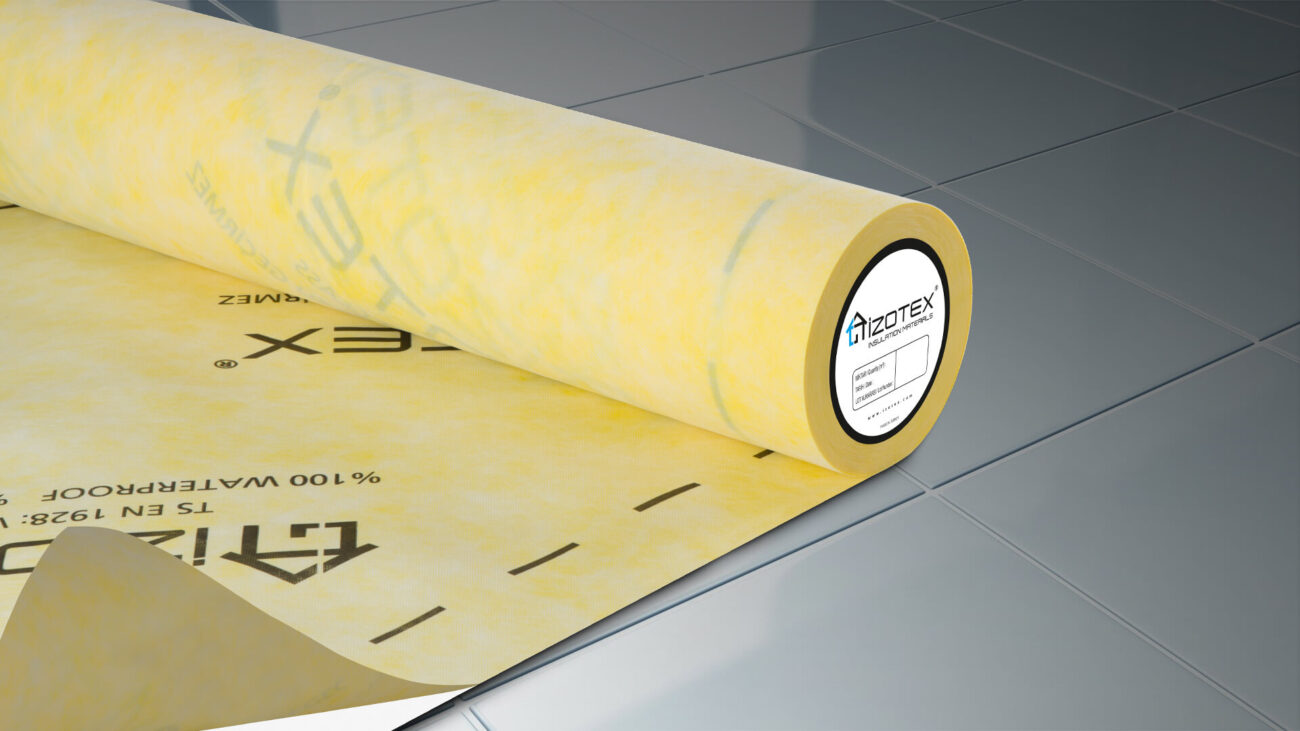

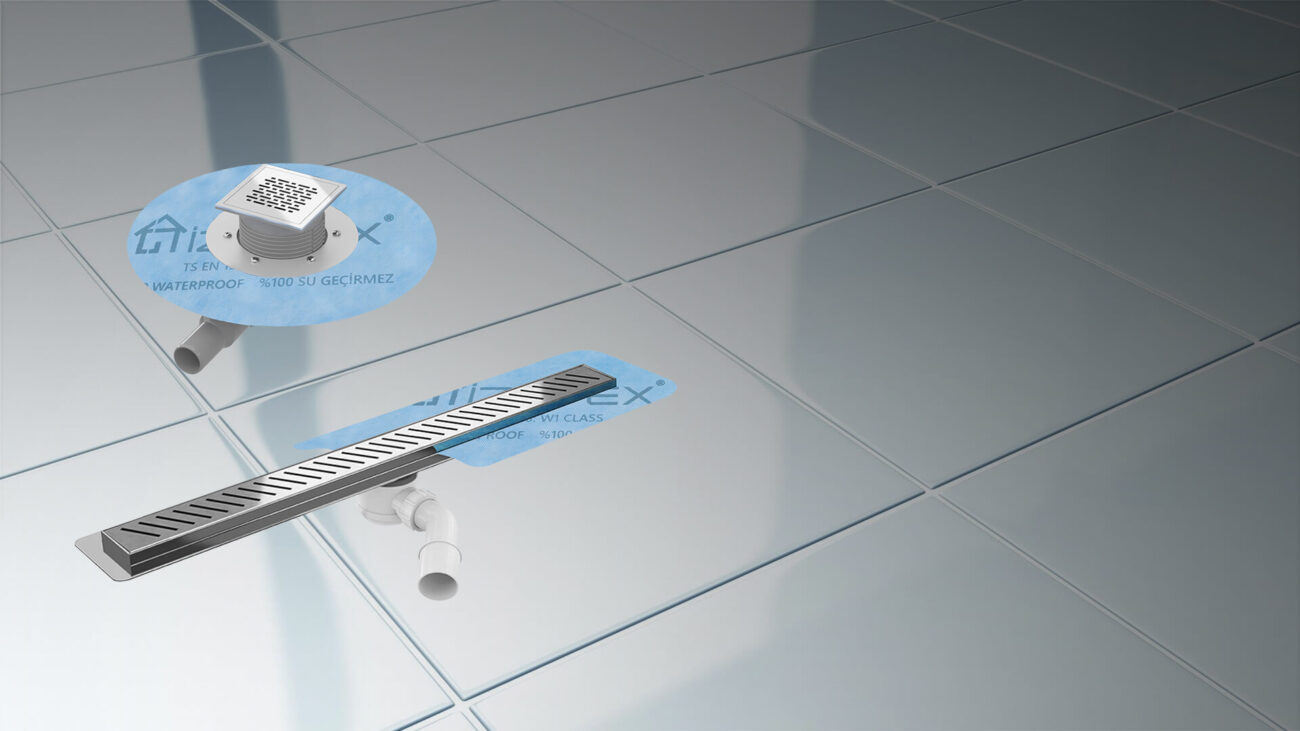

ULTRA Waterproofing Membrane

3 layers vapour retardant waterproofing membrane consisting of PES/PE/PES layers with an enhanced bonding surface. It protects floor and wall substrates from water penetration and moisture passage in wet areas.

Private Label Form

DESCRIPTION

It is a three-layer waterproofing and damp-proofing membrane used under tiles. It consists of durable PES/PE/PES layers that protect floor and wall surfaces from water and moisture. The special texture of ULTRA provides strong adhesion with adhesives and also provides an ideal surface for laying tiles.

USAGE AREAS

- Bathrooms

- Terraces

- Flat roofs

- Balconies

- Water Tanks

- Pools

PRODUCT SIZES

| Product Name | Width | Lenght | Dimension | Weight |

| IZOTEX ULTRA | 100 cm | 30 meter | 14x14x100 cm | 7.5 kg/roll |

| IZOTEX ULTRA | 100 cm | 50 meter | 18x18x100 cm | 12.0 kg/roll |

PROPERTIES

- It is 100% waterproof and has a moisture-proof structure.

- It does not cause cracking with its flexible and bendable structure.

- Thanks to the special polyester fiber structure on both sides, it provides strong adhesion with all adhesives.

- After it is applied, it creates an optimum surface for tiling.

- It can be used in both indoor and outdoor applications.

- It is easy to work with, it can be easily measured with a knife or scissors.

- Due to its light weight, it can be easily carried and applied.

CERTIFICATES

You May Also Like

FAQ

Waterproofing membranes consist of three layers. The outer nonwoven layers have been specially selected to increase the adhesion surface area and to increase the bond strength. In addition, it increases the physical strength of the waterproofing membrane and plays an important role in terms of durability. On the other hand, the middle layer, which is waterproof and moisture barrier, prevents the passage of water and moisture.This middle layer is the core of the waterproofing membranes and is supported by the outer special layers.

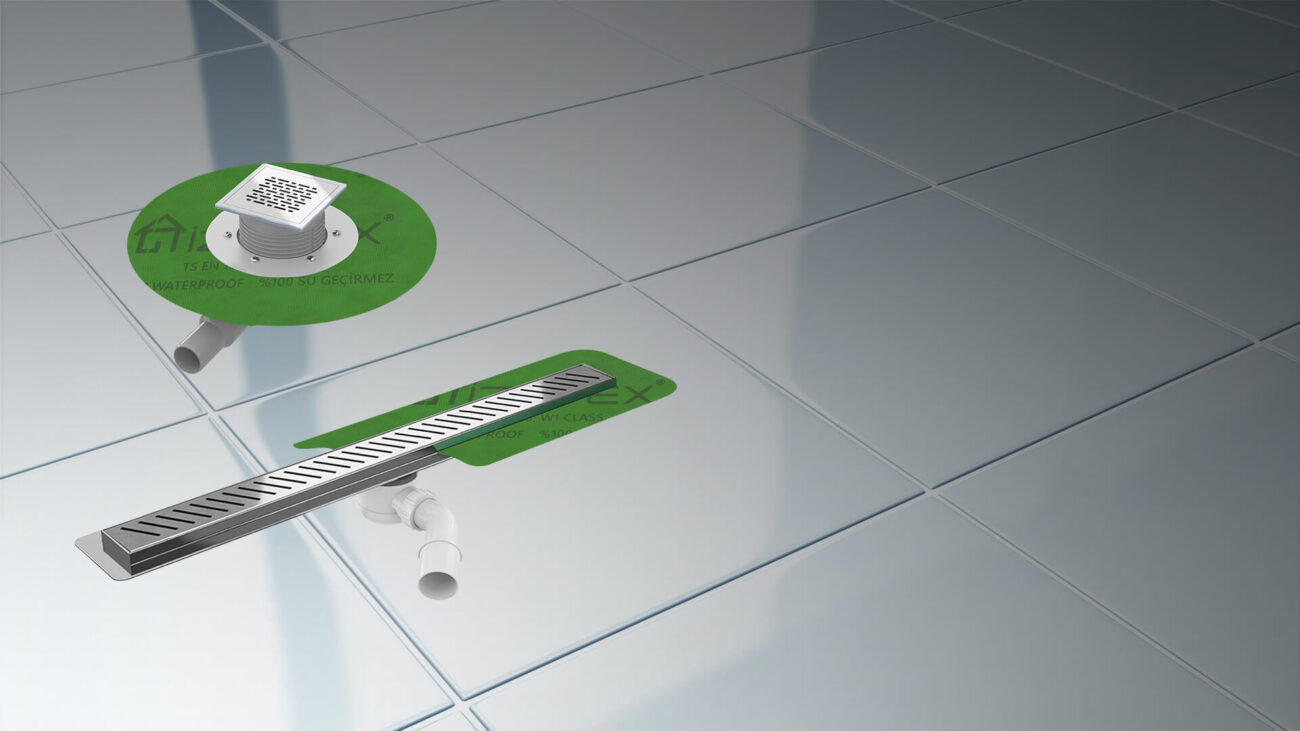

Izotex waterproofing membranes are used for waterproofing wet areas such as bathrooms, terraces, balconies and flat roofs. They can be applied in all areas covered with ceramic, marble, natural stone or protection concrete. In this context, IZOTEX waterproofing membranes can be easily used in both indoor and outdoor waterproofing applications.

Yes, unlike liquid waterproofing systems, a single layer of IZOTEX waterproofing membrane is sufficient for a safe and completely impermeable waterproofing application. It does not require two coats of application.

IZOTEX waterproofing membranes can be applied with a wide variety of adhesives except solvent-based adhesives. Most of the applications are made with C2 S1 class cement-based single or double component adhesives. Depending on the application area and weather conditions, single or double component acrylic or PU based adhesives are also preferred. Flexible two-component adhesives are mainly preferred for bonding joints.

Yes, IZOTEX waterproofing membranes can be used safely in both indoor and outdoor waterproofing applications.

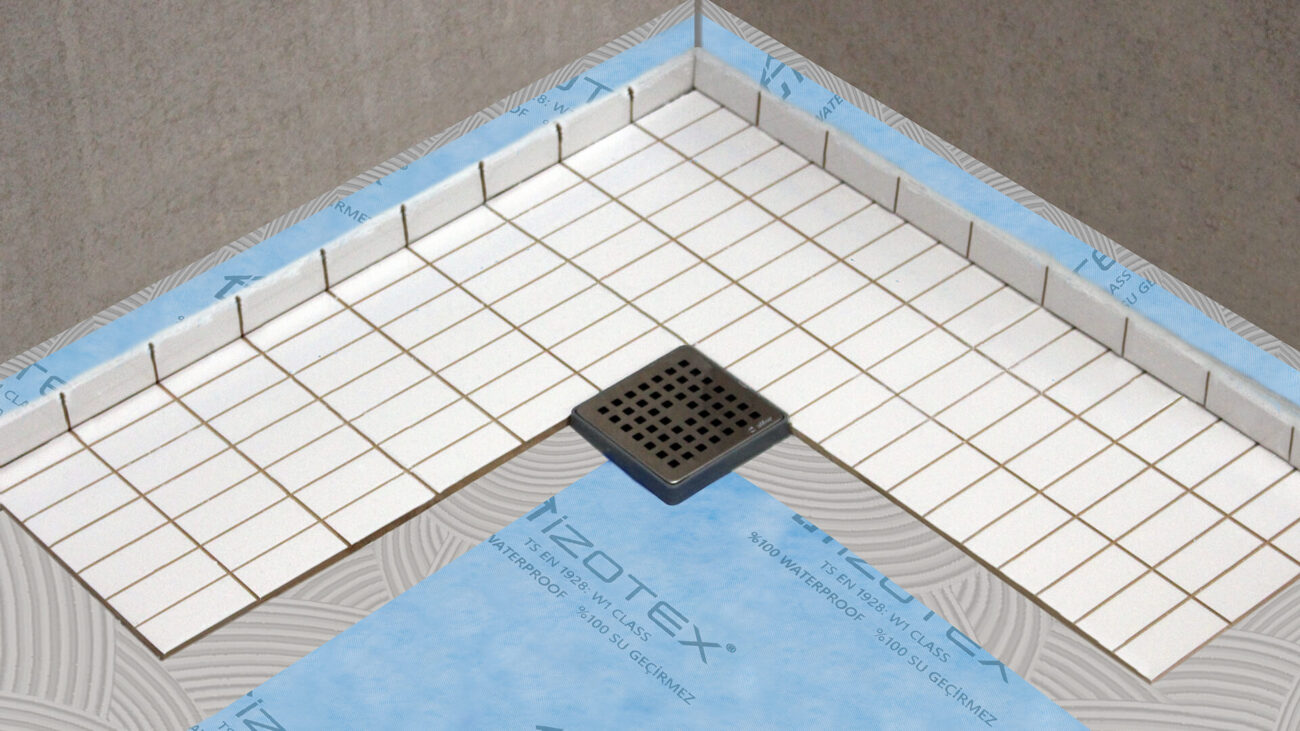

At the final stage of the waterproofing application, Izotex waterproofing membranes must be covered with coating materials such as ceramic, marble and protection concrete. Ceramic and marble blocks are adhered to the waterproofing membrane using flex adhesive. Likewise, after the application of the waterproofing membranes is completed, the protection concrete can be poured directly on the membrane.

No, the front and back surfaces of the membranes are not different. Since both sides of the membrane are laminated with the same material, they have the same properties.

After the Izotex waterproofing membranes are applied to the surfaces, tiling can be started directly.

Full curing of C2 S1 class cementitious adhesives, which are mostly used in applications, requires a certain period of time. However, even when this period is not fully expired, the adhesion strength is sufficient to perform tiling.

Although IZOTEX waterproofing membranes are specially designed to be tiled immediately after the application, it is higghly recommended to start tiling after the adhesives used are fully cured.

The first thing to consider is the surface conditions. The application surface must be dry and clean and must not contain dust and granular parts. Do not forget to check these surfaces before starting the application.

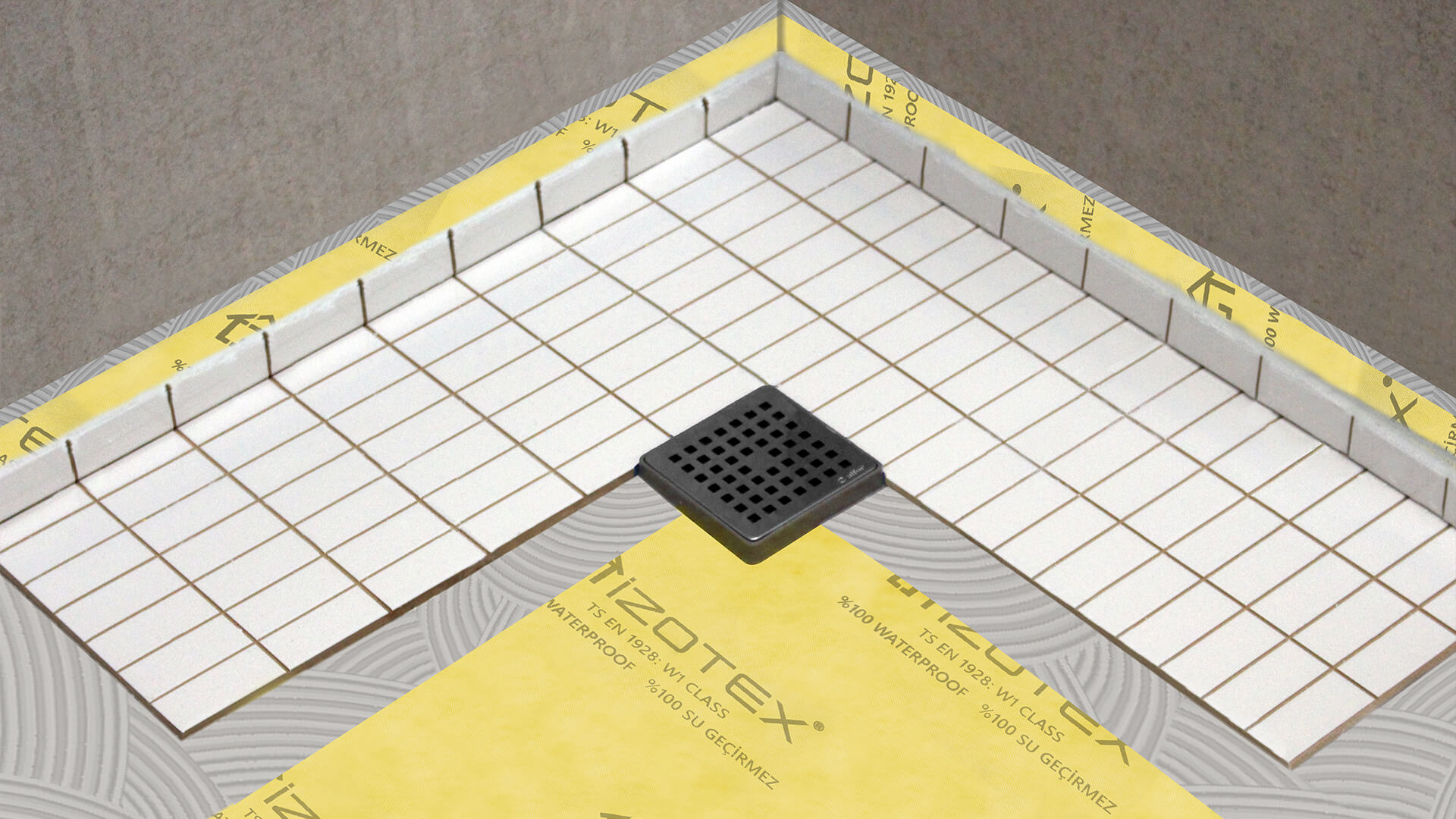

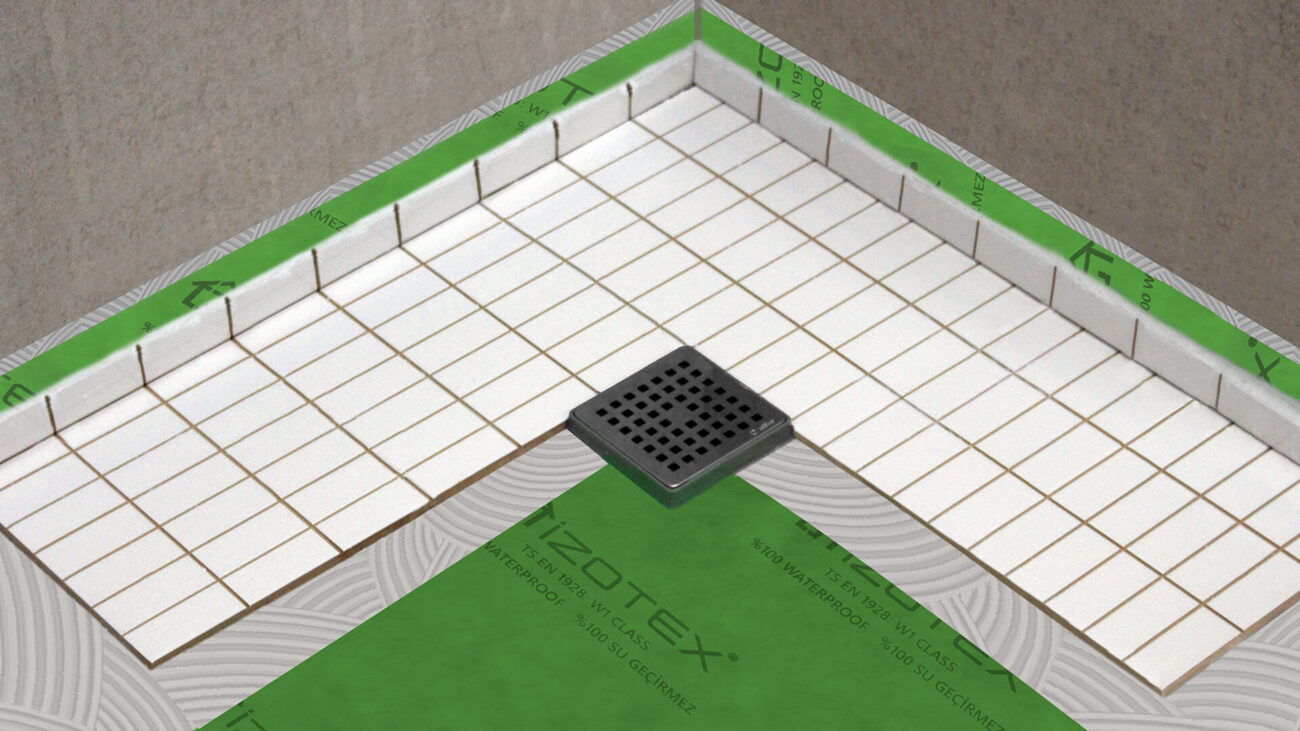

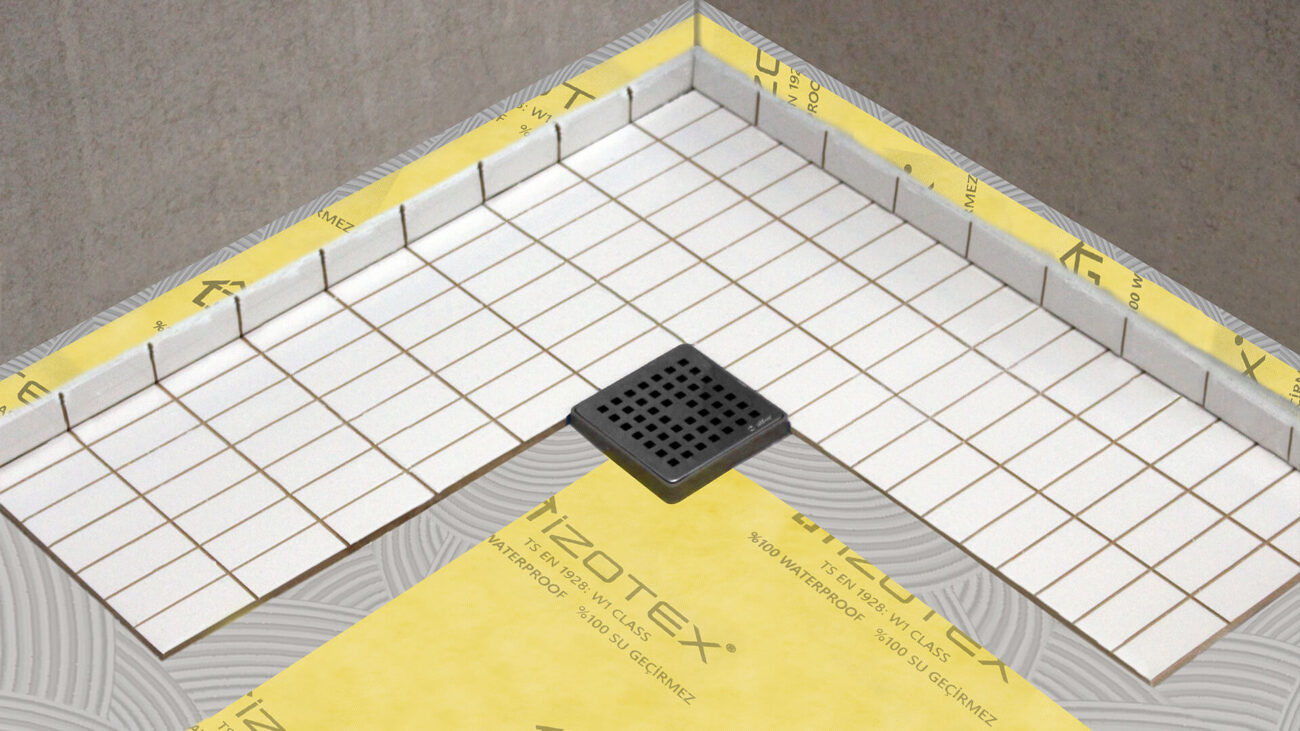

You should protect the edges and corners with IZOTEX inner corner tape or outer corner waterproofing accessories. Be sure to complete the waterproofing application of the corner points before proceeding with the floor and wall applications, and check all the inner/outer corner points.

Make sure that air gaps are removed during the application.

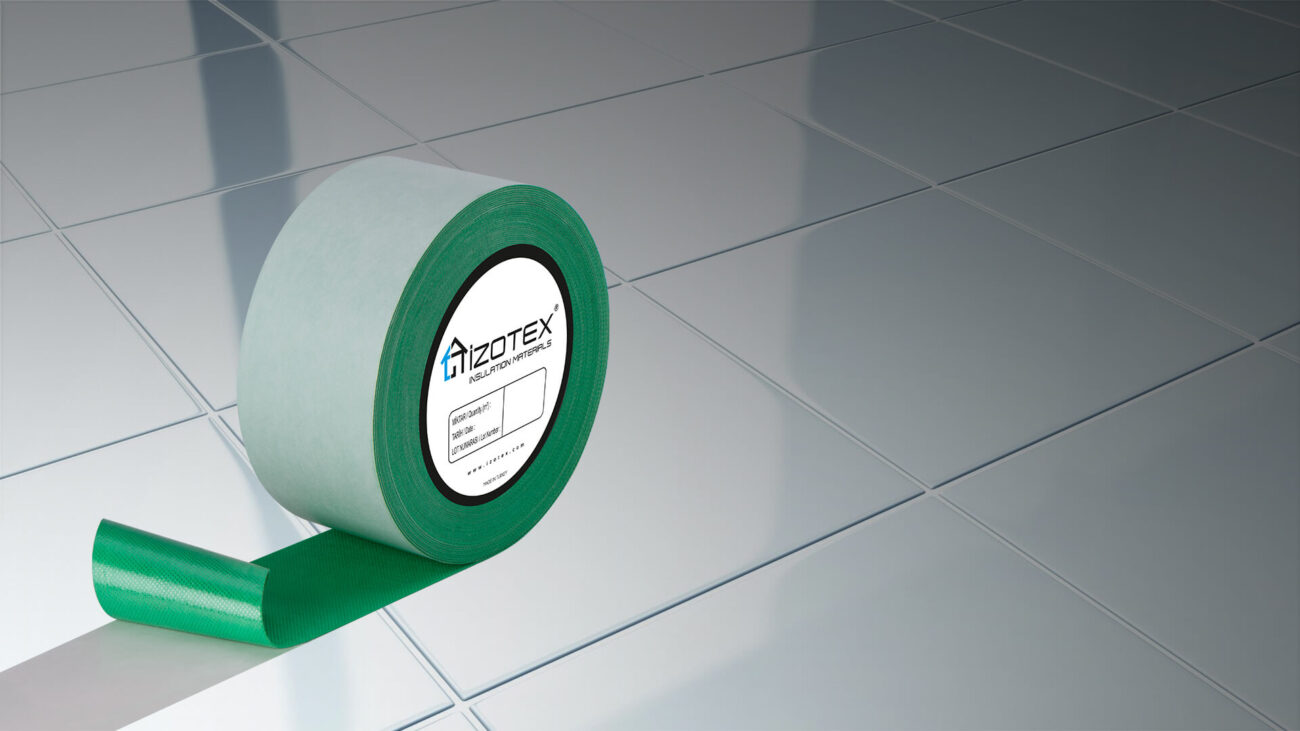

You must seal the joints with Izotex joint sealing tapes.

Be very careful that there are no nails or nails in the application area, it is very important for safe waterproofing that the membranes are not punctured.

Finally, Izotex membranes must be covered and protected with ceramic or concrete and must not left exposed.