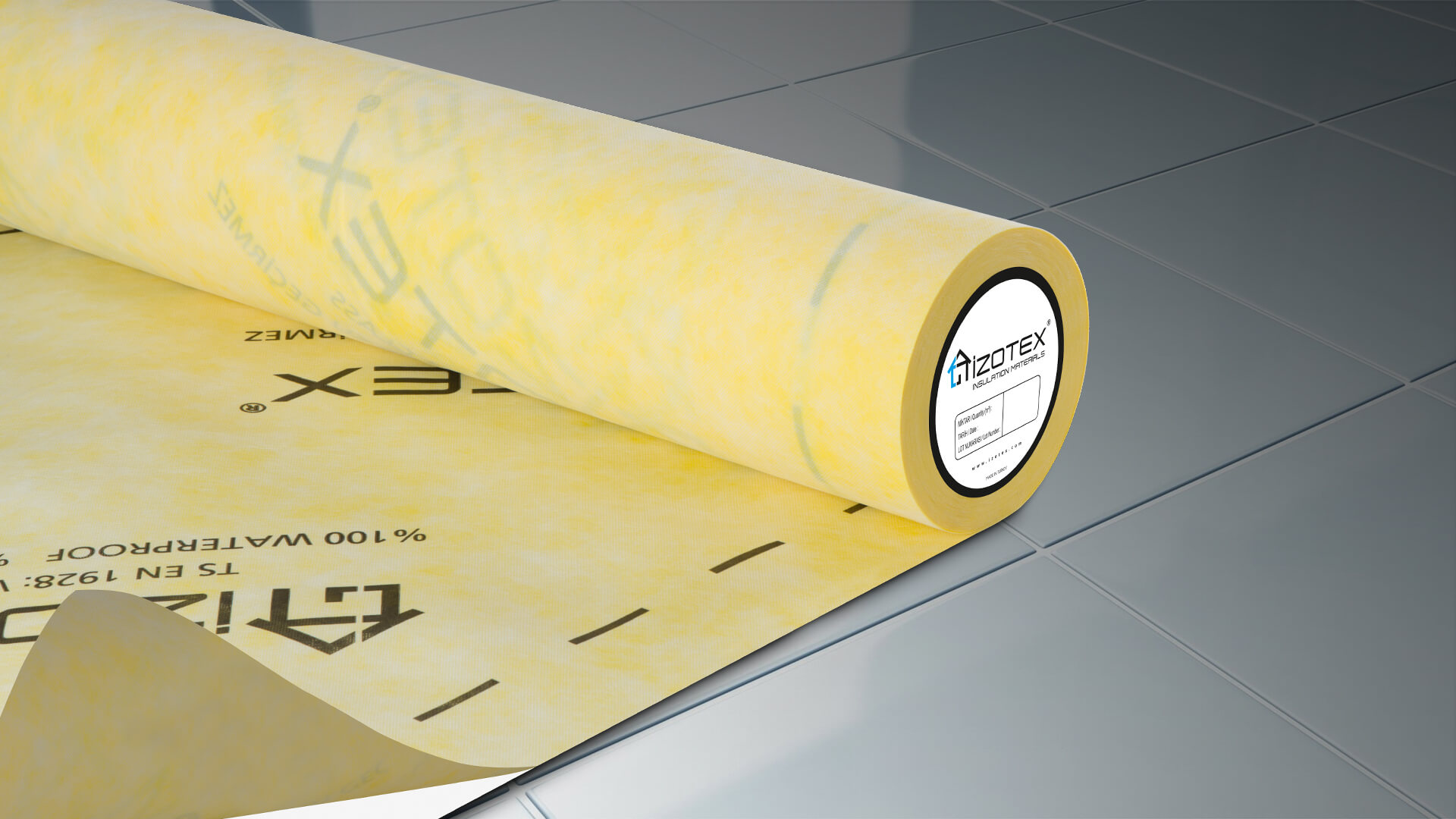

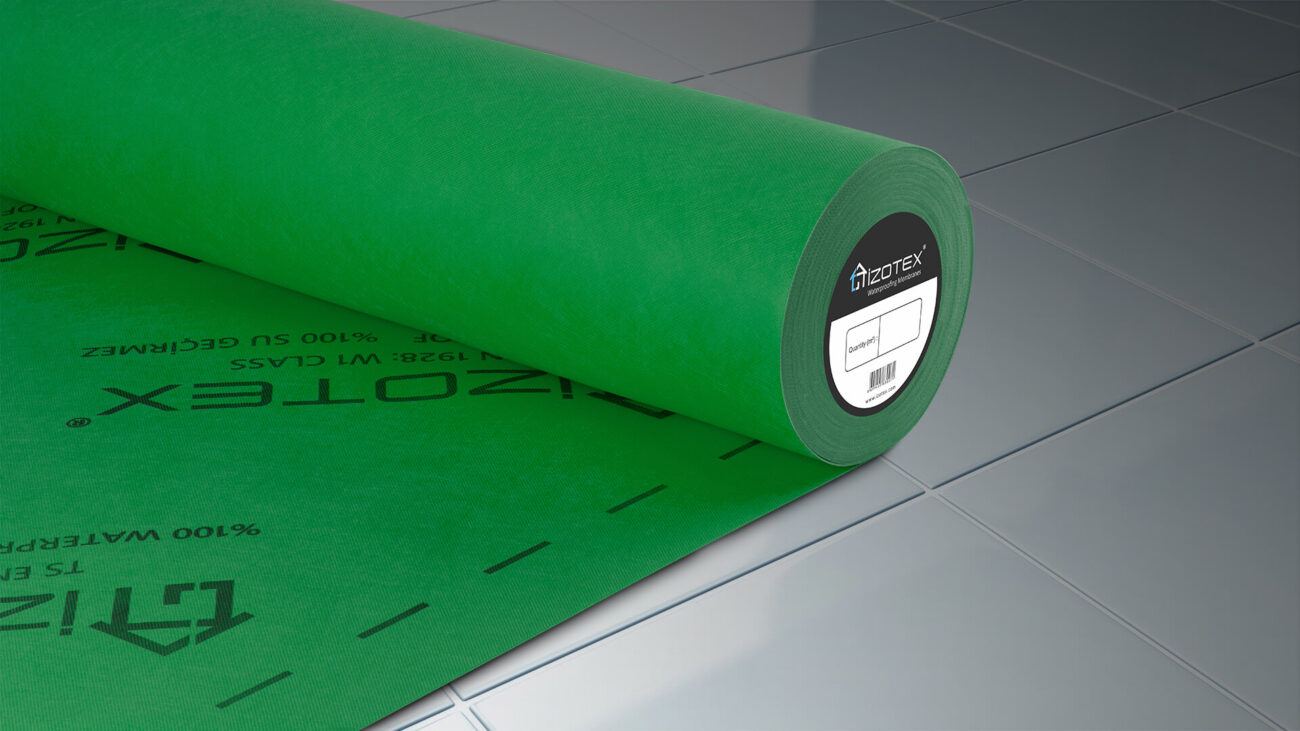

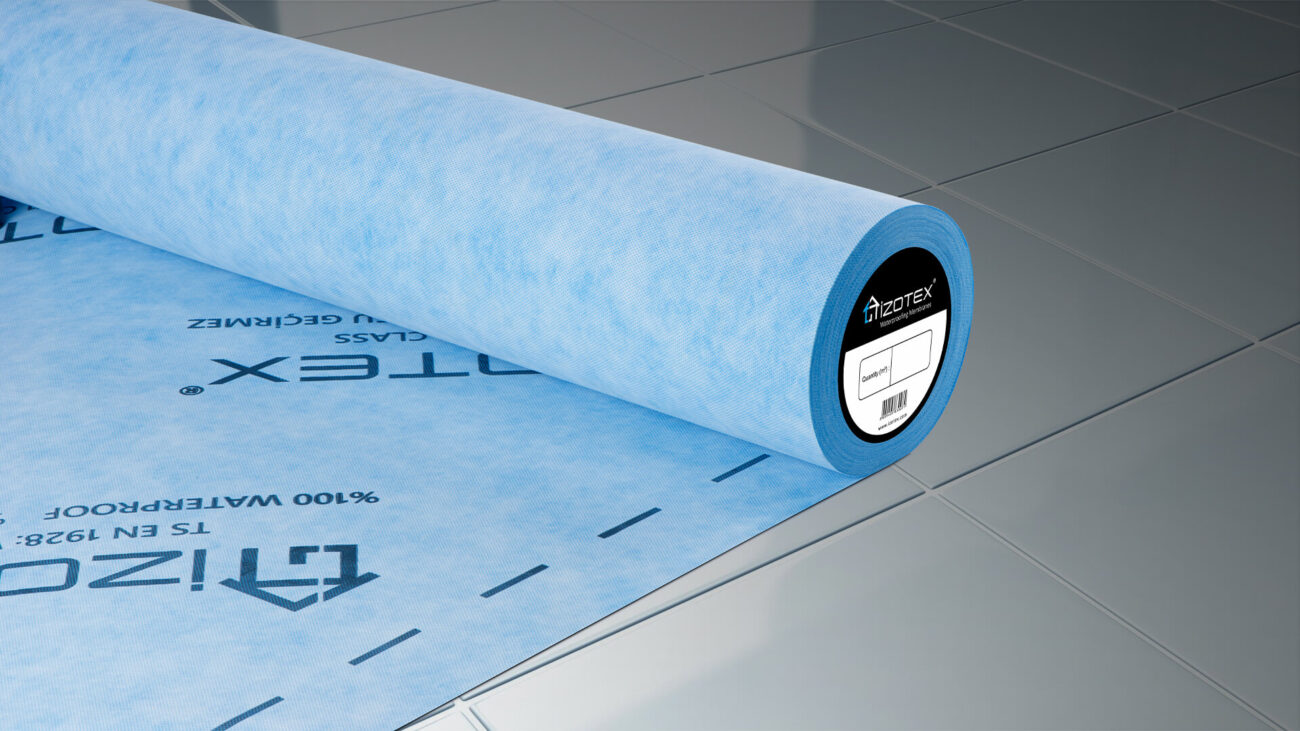

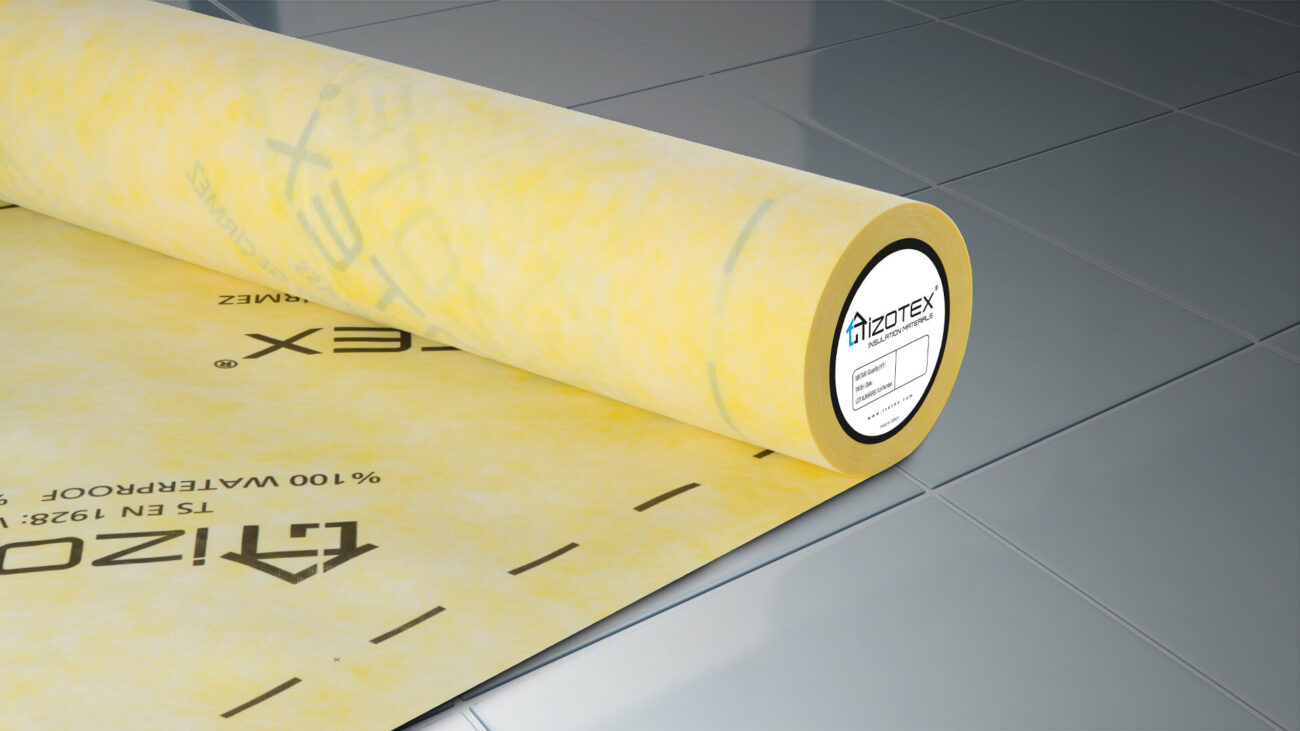

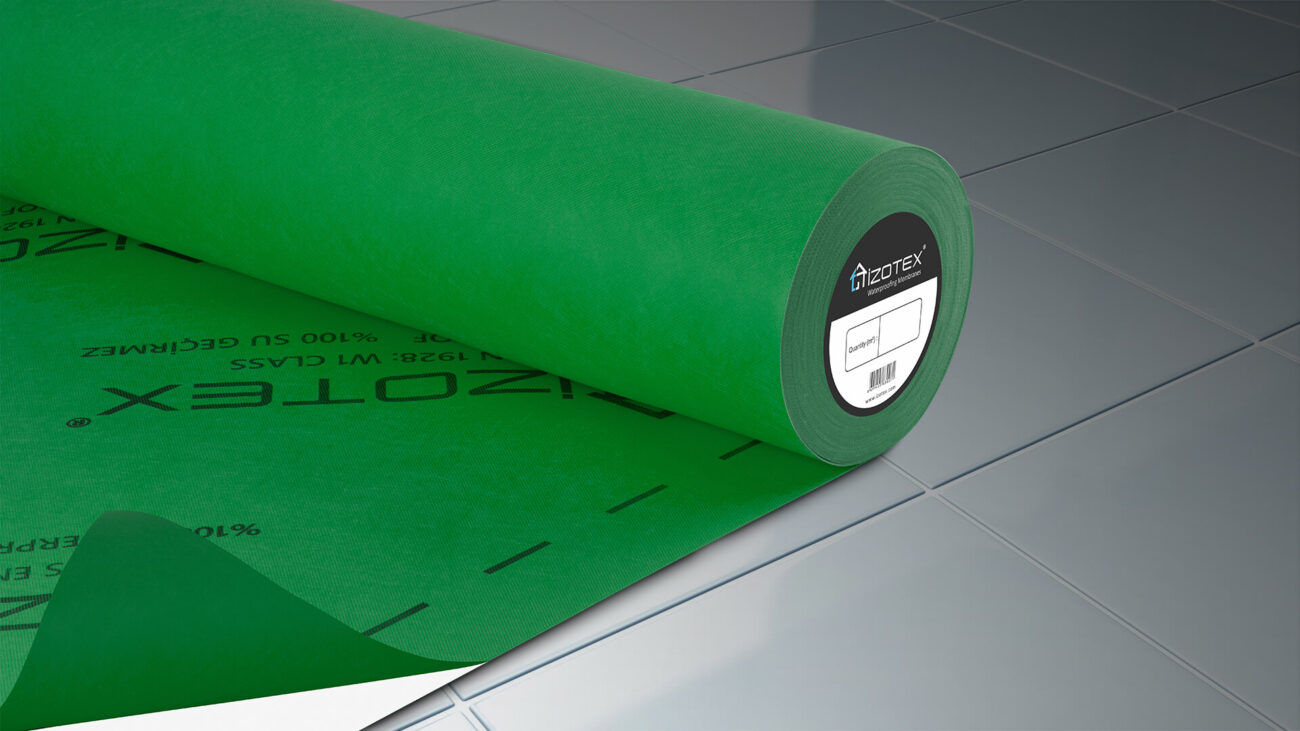

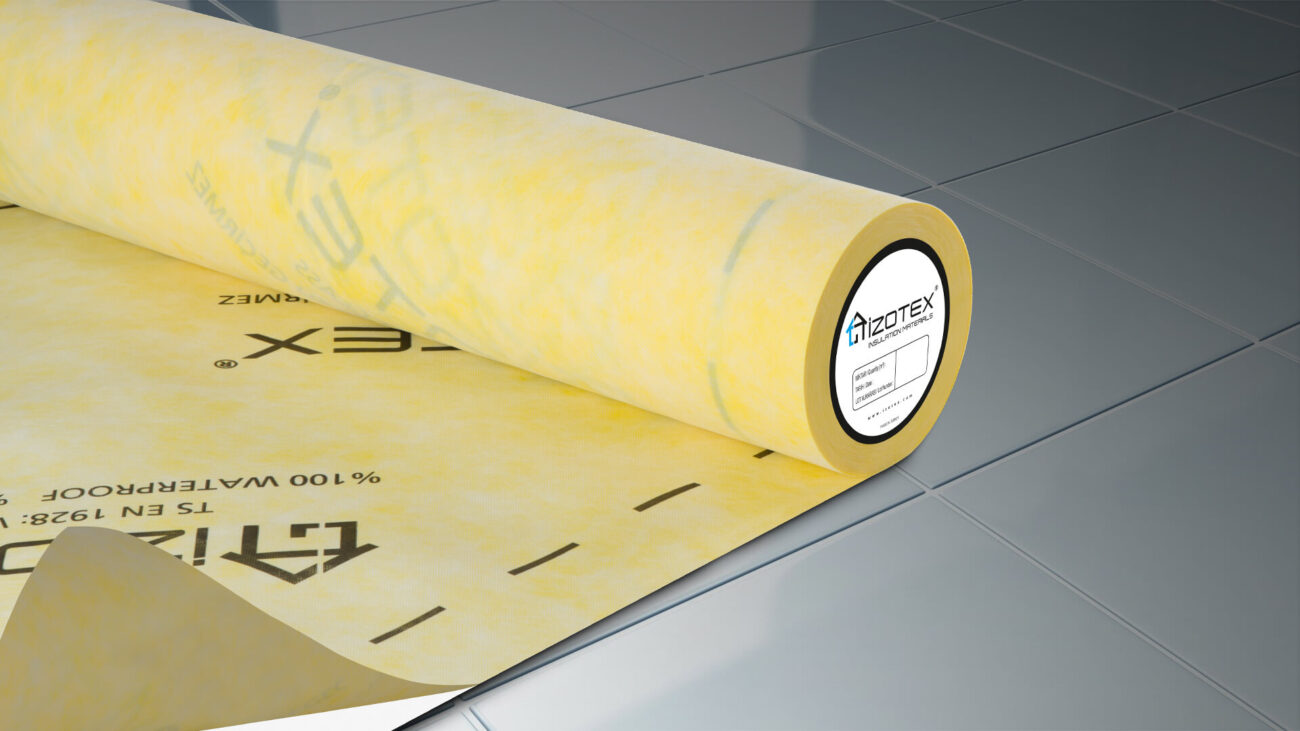

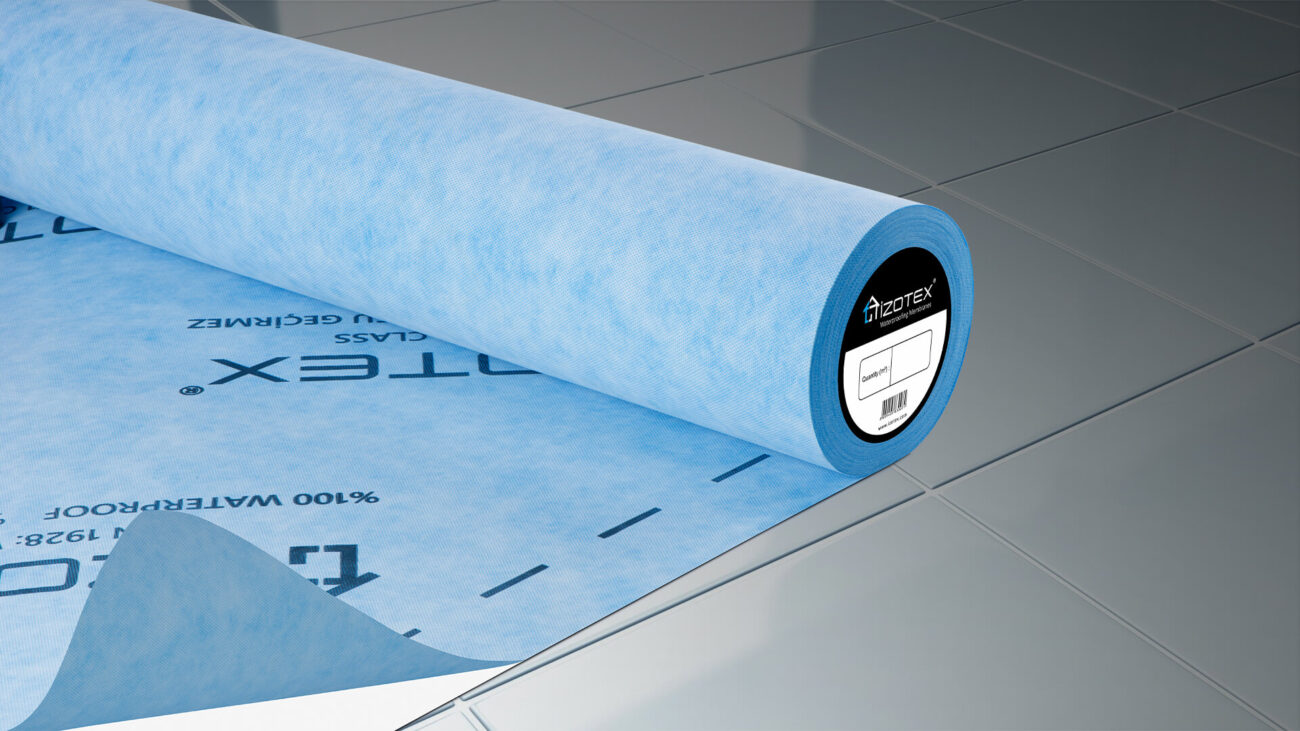

ULTRA PLUS+ Waterproofing Membrane

Five layers self-adhesive waterproofing membrane consisting of PES/PE/PES/A/P layers that can be directly applied to the walls and the floors without using additional sealing products to ensure waterproofing.

Private Label Form

DESCRIPTION

It is a 100 cm wide, fully self-adhesive version of the ULTRA waterproofing membrane. It can be applied directly to walls and floors by simply peeling and sticking, without the use of additional adhesive to provide waterproofing.

USAGE AREAS

- Bathrooms

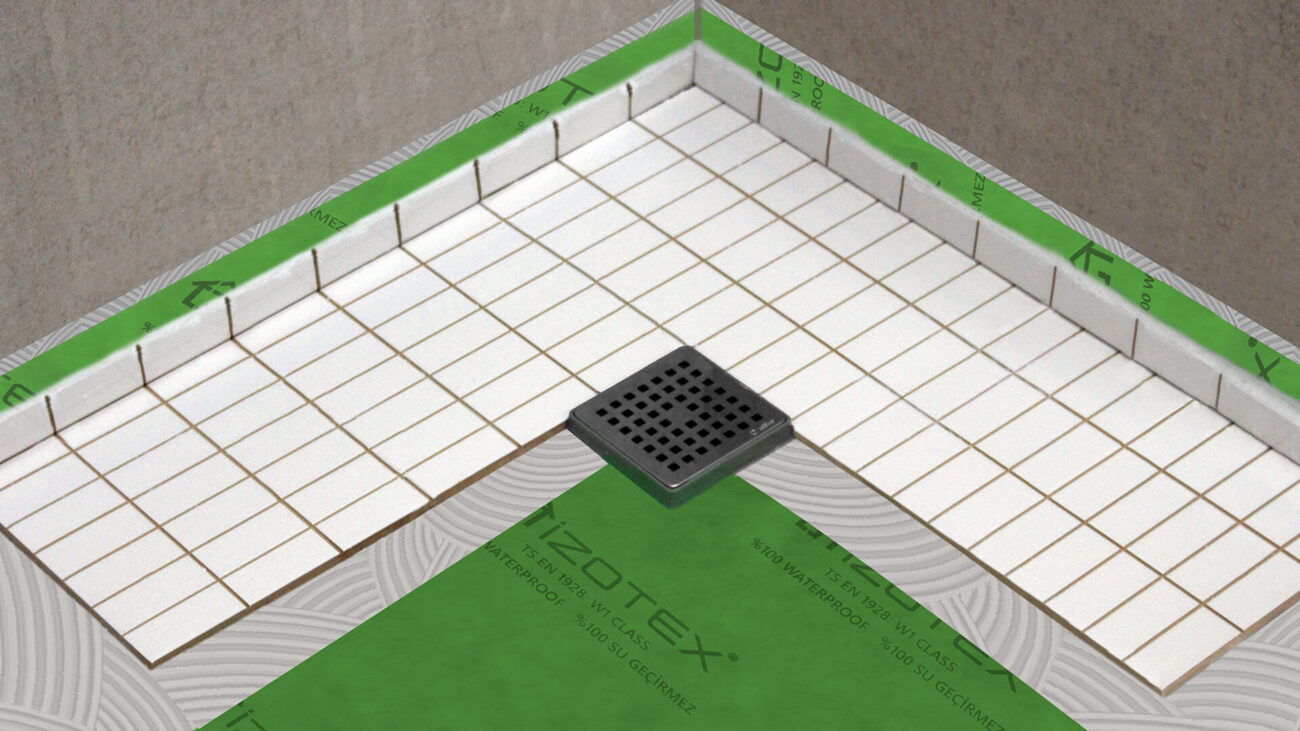

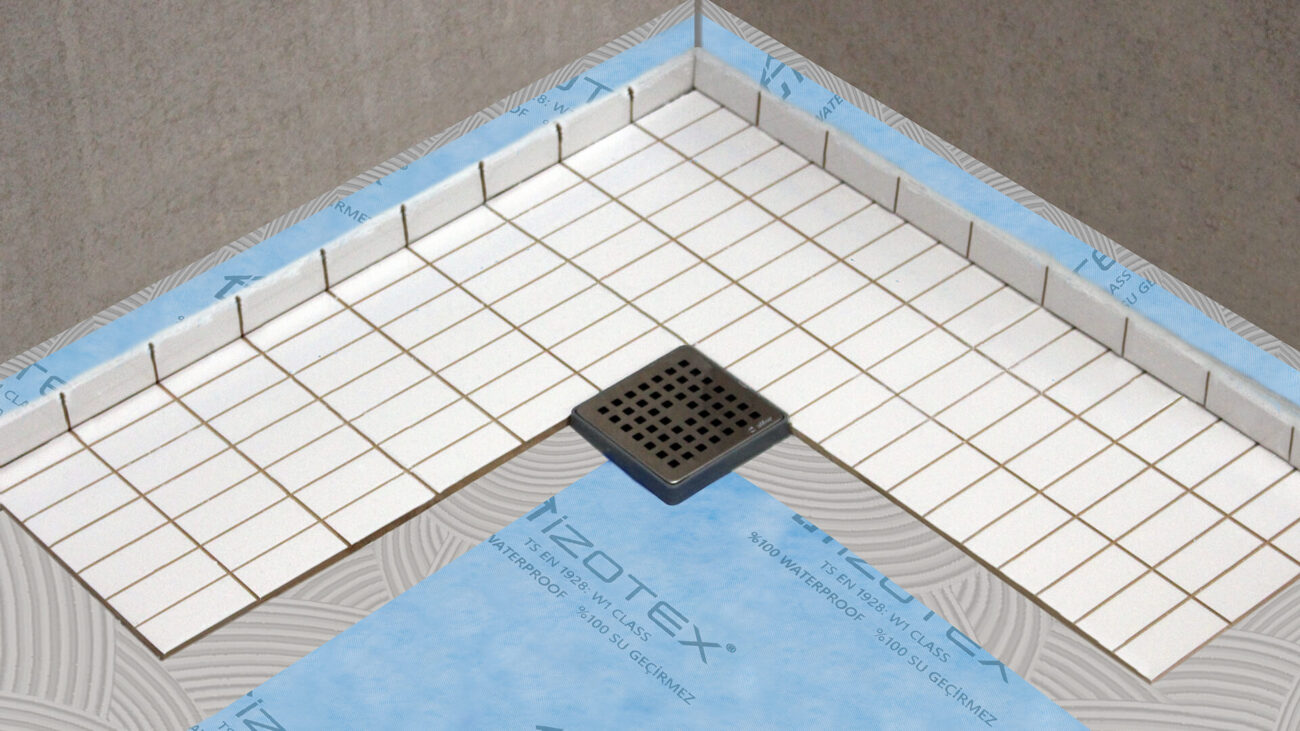

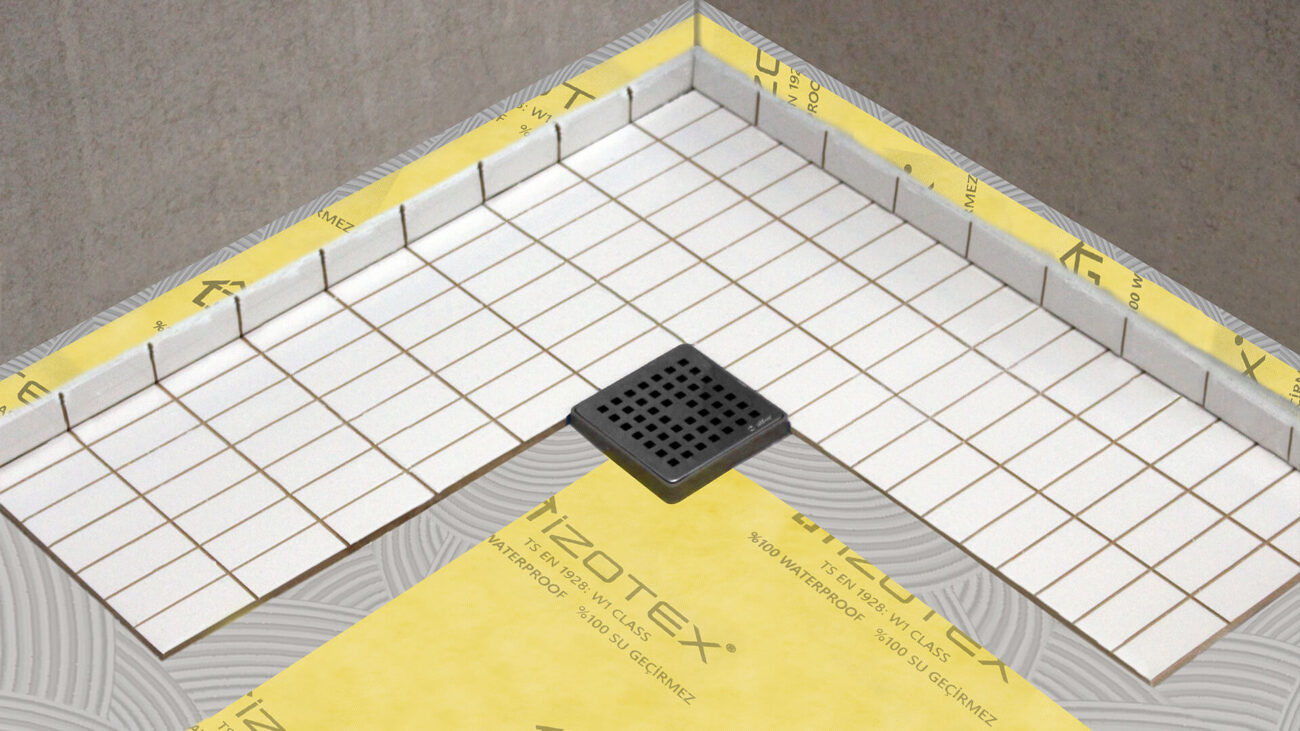

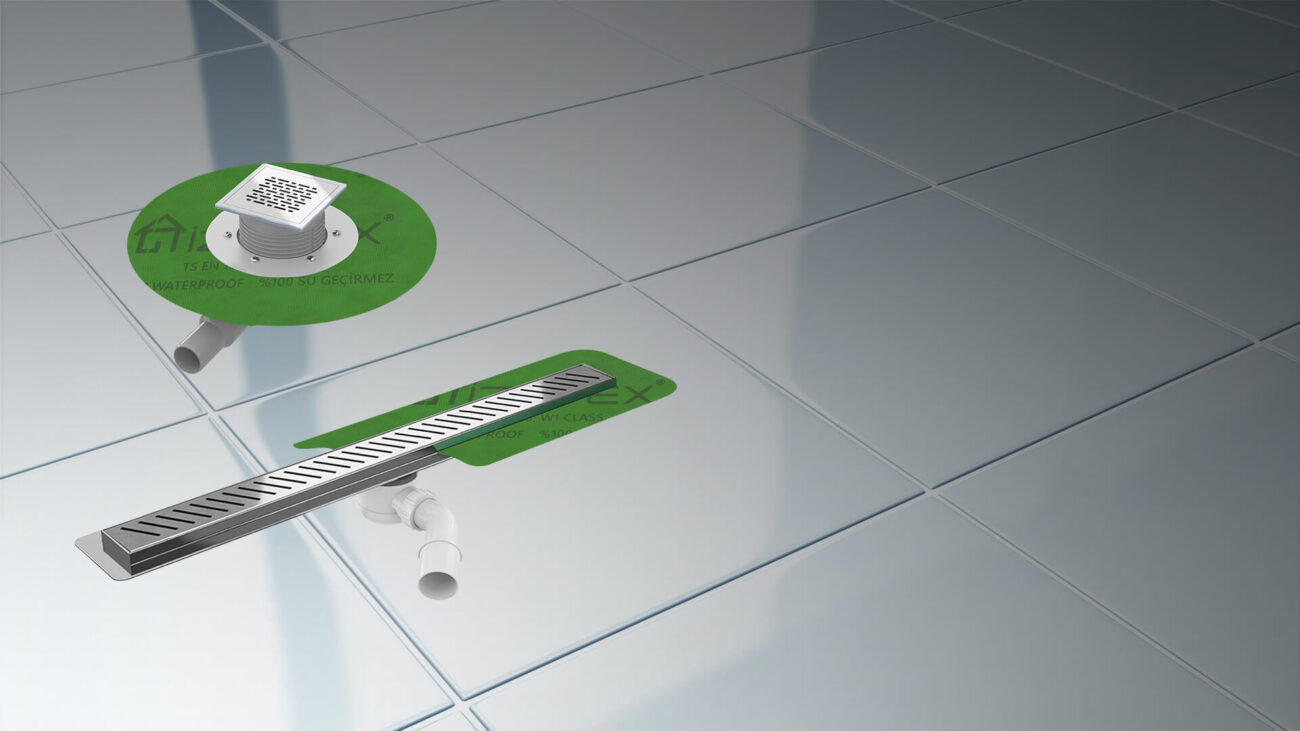

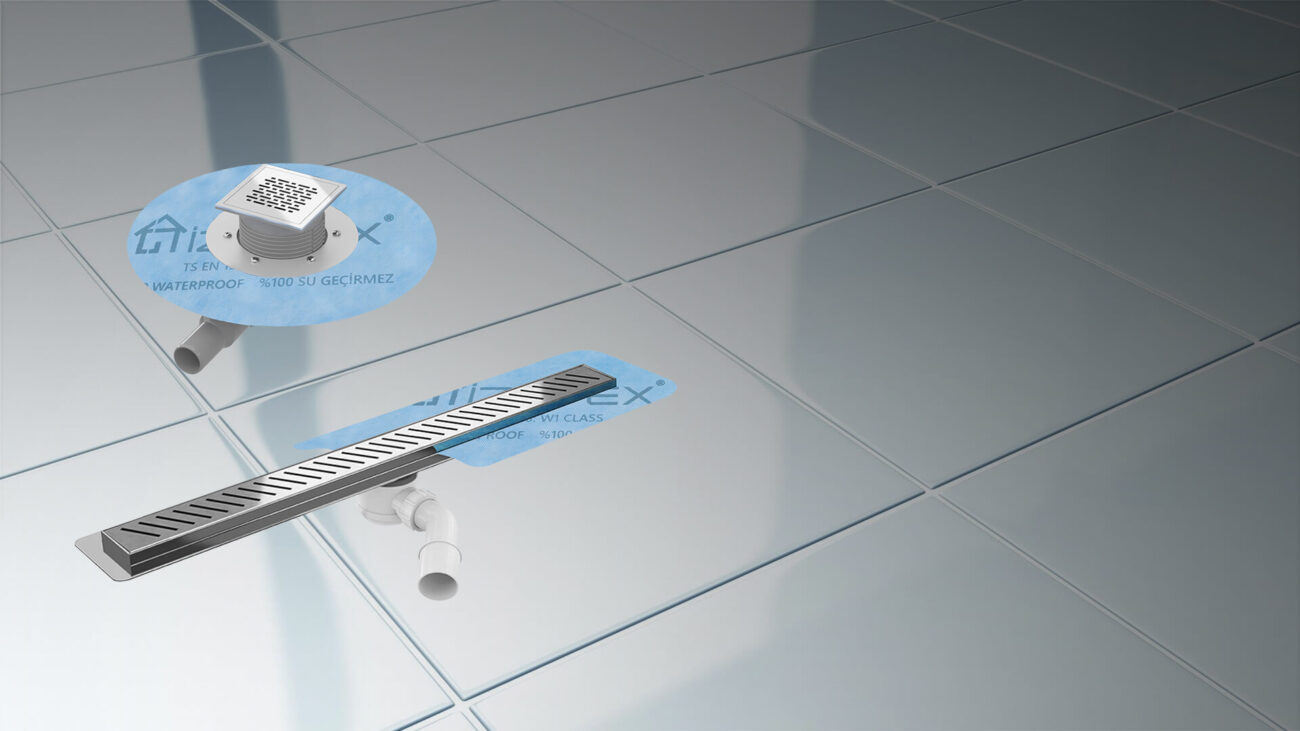

- Shower Drains

- Terraces

- Flat roofs

- Balconies

PRODUCT SIZES

| Product Name | Width | Lenght | Dimension | Weight |

| ULTRA Plus+ | 150 cm | 30 meter | 18x18x150 cm | 13.0 kg/roll |

| ULTRA Plus+ | 150 cm | 50 meter | 21x21x150 cm | 21.0 kg/roll |

PROPERTIES

- It can be directly bonded to floor and wall surfaces without using any additional sealing product.

- The self-adhesive membrane shortens the bonding process and saves time during installation.

- The front face of the membrane is compatible with almost every type of adhesive excluding solvent-based adhesive.

- ULTRA Plus+ can be directly tiled after its installation.

- The back of the membrane is coated with a specially formulated adhesive, and the adhesive is protected with protective liner.

- It can be used in both indoor and outdoor areas.

CERTIFICATES

You May Also Like

FAQ

Textile membranes consist of three layers. The outer layers have been specially selected to increase the adhesion surface area and to increase the bond strength. In addition, it increases the physical strength of the waterproofing membrane and plays an important role in terms of strength. On the other hand, the middle layer, which is waterproof and moisture barrier, protects the surfaces from water, humidity and humidity. This middle layer is the core of the waterproofing membranes and is supported by the outer special layers.

Izotex textile membranes are used for waterproofing wet areas such as bathrooms, terraces, balconies and flat roofs. A waterproofing cover can be applied in all areas covered with ceramic, marble, natural stone or protection concrete and taken under protection. In this context, IZOTEX waterproofing membranes can be easily used in both indoor and outdoor waterproofing applications.

It is also used as a waterproofing skirt around the drain by being integrated into the products by the manufacturers of drain systems and shower channels.

Yes, a single layer of IZOTEX waterproofing membranes is sufficient for a safe and fully impermeable waterproofing application, unlike sliding insulations. It does not require two coats of application.

IZOTEX waterproofing membranes can be applied with other adhesive groups except solvent-based adhesives. Most of the applications are made with C2 S1 class cement based single or double component adhesives. Depending on the application area and weather conditions, single or double component acrylic and PU based adhesives are also preferred. Flexible two-component adhesives are mainly preferred for bonding joints.

Yes, IZOTEX waterproofing membranes can be used safely in both indoor and outdoor waterproofing applications.

At the final stage of the waterproofing application, Izotex waterproofing membranes can be covered with coating materials such as ceramic, marble and protection concrete. Ceramic and marble blocks are adhered to the waterproofing membrane by using suitable adhesive. Likewise, after the application of the waterproofing membranes is completed, the protection concrete can be poured directly on the cover.

No, membranes do not have an anterior or posterior surface. Since both sides of the covers are made of the same material, they have the same properties.

One side of the self-adhesive waterproofing membranes is covered with adhesive and silicone paper, and the other side is covered with a special PP layer compatible with adhesives. In order to apply the self-adhesive waterproofing membrane, the siliconized paper is removed and the adhesive underneath is adhered to the surface to be applied.

After the Izotex waterproofing cover is applied to the surface, the ceramic coating process can be started directly.

C2 S1 class cement based ceramic/granite adhesive, which is mostly used in applications, requires a certain period of time for full curing. However, even when this period is not fully expired, the adhesion strength is sufficient to perform ceramic coating.

Although the special surfaces of IZOTEX waterproofing membranes are specially designed to be able to switch to the ceramic coating process immediately after the application is finished, it is recommended to switch to the ceramic coating process after the adhesives used are fully cured.

The first thing to consider is the surface conditions. The application surface should be dry and clean and should not contain dust and granular parts. Do not forget to check the surface before starting the application.

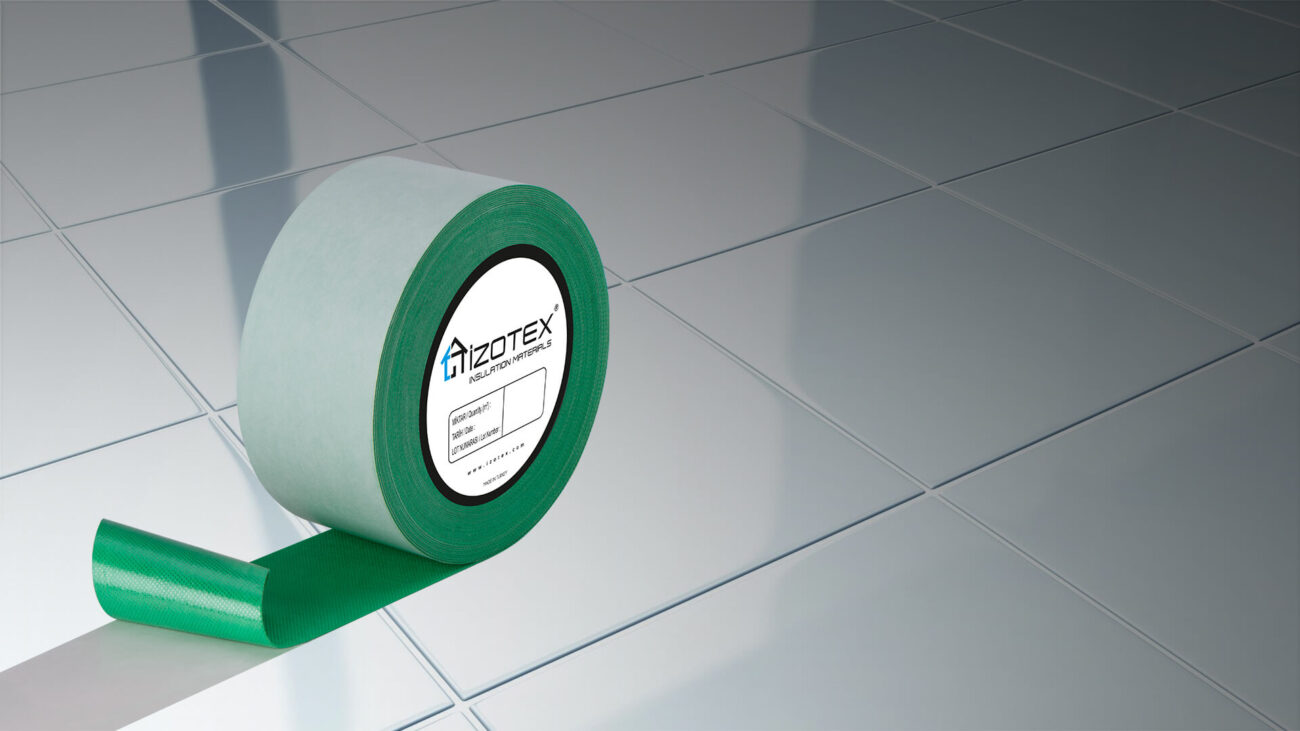

You should protect the edges and corners with IZOTEX inner corner tape or outer corner waterproofing accessories. Be sure to complete the waterproofing application of the corner points before proceeding with the floor and wall applications, and check all the inner/outer corner points.

When waterproofing wet areas such as bathrooms, terraces, balconies and flat roofs, make sure that air gaps are removed during the application. During the adhesion of the cover to the floor and wall surfaces, spatula etc. should be applied on the cover. you can easily remove air gaps with a tool and provide a better adhesion.

You must insulate the joints with the IZOTEX TAPE product or by using a chamfer tape with the appropriate adhesive.

Nails etc. that may pierce the covers during application. Be very careful that there are no structures, it is very important for safe waterproofing that the covers are not punctured.

Finally, be sure to cover the covers with coating materials such as ceramic, marble, protection concrete. The waterproofing membranes should not be exposed and should be covered.